Stack Monitoring System

Why Stack Monitoring Is Important

Monitoring emissions from industrial stacks is essential for maintaining compliance with national air quality standards and protecting the environment. A Stack Online Monitoring System provides real-time data on pollutants like particulate matter, SO₂, NOx, and CO, allowing industries to take corrective action before exceeding permissible limits. Continuous monitoring ensures transparency, reduces the risk of penalties, supports sustainability goals, and safeguards the health of nearby communities and ecosystems.

Why Choose PT Ecological Services for Stack Monitoring?

With over 15 years of domain expertise, PT Ecological Services delivers highly accurate and reliable Stack Online Monitoring Systems tailored to your industry’s needs. Our solutions are designed to comply with CPCB/SPCB norms and integrate seamlessly with regulatory servers. From installation to data reporting, we ensure end-to-end support, robust sensor technology, SCADA compatibility, and proactive maintenance—making us a trusted partner for air pollution compliance and environmental accountability.

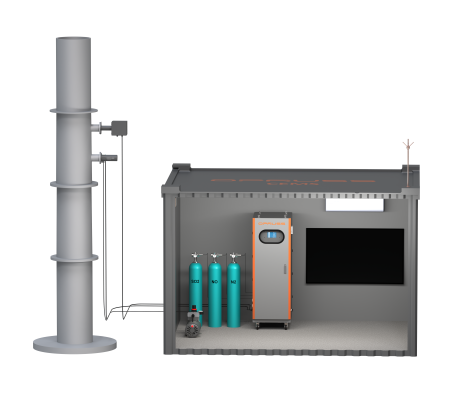

Key Features of Our Stack Monitoring System

- Easy & Secure Access – Powered by ECOLYSER, the platform enables safe and simple access to data from all registered devices.

- Compact Design – Small in size yet powerful in function, it accurately measures NOx, SO₂, CO, CO₂, O₂, and meteorological parameters.

- Rugged Build – Housed in a robust shelter that ensures performance even in extreme environmental conditions.

- Auto Temperature Control – Features an in-built temperature dispenser for stable readings unaffected by humidity or heat.

- Future-Ready Functionality – Supports remote data access, area-grid mapping, and pollution heat map prediction.

- High-Speed Processing – Ultrafast system with 24×7 support for uninterrupted monitoring.

- Urban Grid Monitoring – Offers multi-parameter tracking for comprehensive urban environmental assessments.

| Model name | ENDA-5000 |

| Measurement method | NDIR |

| Measurement range | 200-500ppm |

| Measurement repeat | 0.5%FS |

| Frequency | 50/60Hz |

| Power Supply | Ac 100 -+ 15V (85V-115V) |

| Power consumption | About 800VA |

| Enclosure | Independent outdoor installation |

| Measurement interval | Within 60seconds (Td+T90 from equipment intake area) (sample flow0.6L/min) (within 240 seconds for SO2 only) |

| Output | DC4 to 20mA (absolute output) (DC 0 to 16mA/ DC 0 to 1V/DC 1 to 5V optional) Max.12 Output systems |

| Material | SUS-316 stainless steel, SUS-304 stainless steel, Teflon, polypropylene, polyethylene, flour rubber, PVC, PVDF and glass |

| APPLICATIONS | |

| Real monitoring in Industrial areas | |

| Deriving heat maps for future trends. | |

| Environmental monitoring in commercial communities and small cities. | |

| ADVANTAGES | |

| No need for optical adjustment. | |

| A stable zero point. | |

| Cross flow modulated non dispersive infrared (NDIR) detection is renowned for long term stability. | |

| Continuous cleaning keeps the cell clean. | |

| An interference compensation detector compensates for interference from H2O during NOx and SO2 measurement. | |

| A CO2 sensor constantly measures and makes corrections to compensate for CO2 interference in NOx measurements. | |

The ENDA-5000 series by HORIBA is a measuring unit designed for stack gas analysis. This device provides continuous, simultaneous, and highly precise measurements of NOx, SO2, CO, CO2, and O2. It’s utilized for monitoring emissions from stack facilities, conducting air quality assessments, and evaluating the effectiveness of pollution control measures.

Applicable for:

Industries, Urban Municipalities, Smart Cities, Construction Zones, Highways, and Pollution-prone areas needing real-time environmental monitoring.

FAQ

By providing continuous, real-time emission data, the system ensures industries stay within legal limits, avoid penalties, and take corrective actions before violations occur.

It accurately measures NOx, SO₂, CO, CO₂, O₂, and key meteorological parameters.

Yes, it’s fully compliant with CPCB/SPCB guidelines and supports data integration with regulatory servers.

Absolutely—it’s built with a rugged shelter and temperature control to ensure stable readings.

Real-time alerts, automated measurements, and remote access help operators make faster decisions, optimize emissions control, and reduce downtime.

Yes, the system enables real-time remote access, data analytics, and pollution heat map predictions.

It’s ideal for industries, smart cities, highways, construction zones, and pollution hotspots.

It uses NDIR detection with interference compensation for H₂O and CO₂, continuous cell cleaning, and a stable zero point for reliable, long-term performance.

It ensures real-time emission tracking to meet pollution control norms and protect public health.

It accurately measures NOx, SO₂, CO, CO₂, O₂, and key meteorological parameters.

Yes, it’s fully compliant with CPCB/SPCB guidelines and supports data integration with regulatory servers.

Absolutely—it’s built with a rugged shelter and temperature control to ensure stable readings.

We offer 15+ years of expertise, end-to-end support, SCADA compatibility, and proactive maintenance.

Yes, the system enables real-time remote access, data analytics, and pollution heat map predictions.

It’s ideal for industries, smart cities, highways, construction zones, and pollution hotspots.