Though it presents a major environmental problem—the creation of wastewater loaded with toxins—industrialization is a major driver of economic development. Untreated, this effluent can irreversibly damage the environment generally, human health, and aquatic ecosystems.

Here, Effluent Treatment Plants (ETPs) act as vital environmental protectors, guaranteeing that industrial waste is processed to safe standards before either disposal or reuse.

What is an Effluent Treatment Plant (ETP)?

Removing organic, inorganic, toxic, and non-toxic compounds, an effluent treatment plant (ETP) is a specialist facility that treats industrial wastewater. The treated water is then either safely disposed of or put to use for non-potable needs.

Our specialty at PT Ecological Services is providing technologically sophisticated, custom-designed ETPs guaranteed for regulatory compliance that support sustainability.

Why is an ETP Important?

Not only is installing and maintaining an ETP a legal requirement; it also serves an operational and environmental need. This is the reason:

- avoids polluting native water sources

- lessens environmental hazards and obligations

- guarantees CPCB and SPCB compliance

- promotes water conservation and reuse.

- strengthens CSR projects and brand reputation.

Why Choose PT Ecological’s ETP Solutions?

With over 15 years of industry experience, PT Ecological Services offers complete environmental solutions tailored to your business needs. Our ETP solutions are:

- Custom-Built: Industry-specific systems for pharmaceuticals, textiles, food & beverage, chemicals, and more

- Regulatory-Compliant: Fully aligned with CPCB/SPCB and international standards

- Technologically Advanced: Integration of ASP, MBBR, MBR, SBR, UF, and RO systems

- Energy-Efficient: Designed for minimal energy consumption and reduced OPEX

- Sustainable: Built for Zero Liquid Discharge (ZLD) and high water recovery

- End-to-End: From design to installation, including AMC and system upgrades

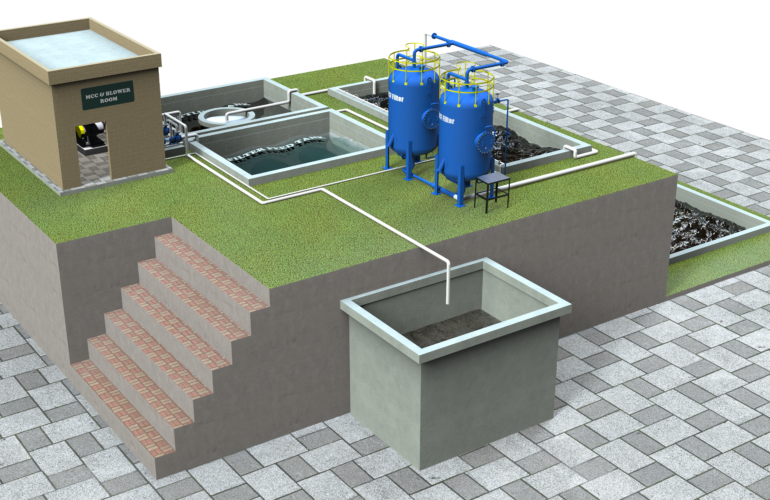

Key Stages of the ETP Process

A well-designed ETP typically follows four critical stages:

- Primary Treatment

- Removal of large particles, grit, and suspended solids through screening and sedimentation

- Removal of large particles, grit, and suspended solids through screening and sedimentation

- Secondary Treatment

- Biological degradation of dissolved organic matter using ASP, MBBR, or SBR processes

- Biological degradation of dissolved organic matter using ASP, MBBR, or SBR processes

- Tertiary Treatment

- Polishing of effluent using technologies such as MBR, UF, or RO to achieve discharge/reuse standards

- Polishing of effluent using technologies such as MBR, UF, or RO to achieve discharge/reuse standards

- Sludge Management

- Dewatering and safe disposal of biosolids and other waste materials

- Dewatering and safe disposal of biosolids and other waste materials

Who Needs an ETP?

Effluent Treatment Plants are critical for industries that generate large volumes of wastewater or toxic effluents, including:

- Pharmaceuticals

- Chemical Manufacturing

- Textile & Dyeing Units

- Food & Beverage Processing

- Paper & Pulp Mills

- General Manufacturing

- CETPs, STPs, and Hazardous Waste Facilities

CPCB Guidelines for ETPs: Key Compliance Standards

To ensure environmental and legal safety, ETPs must adhere to CPCB’s latest technical and quality standards:

Technology Requirements

- ASP (Activated Sludge Process) – Mandatory for effluent loads above 500 KLD

- MBR, MBBR – Preferred for higher efficiency and compact design

Operational Parameters

- Equalization Tank: Minimum 8 hours retention time

- Aeration Systems: DO > 4 mg/L

- Sludge Tanks: For dewatering and safe handling

Effluent Discharge Standards

- pH: 6.5–8.5

- BOD: <10 mg/L

- COD: <50 mg/L

- TSS: <10 mg/L

Sensor & Monitoring Requirements

- pH, TSS, BOD, COD, and flow sensors

- Must support RS-485 Modbus for real-time data connectivity

Reuse Provisions

- Treated water must be reused for flushing, gardening, and other non-potable applications

Key Benefits of Installing an ETP

- Water Recovery & Reuse – Reduces freshwater consumption

- Operational Savings – Lowers water procurement and disposal costs

- Real-Time Monitoring – Sensor-integrated systems ensure 24/7 compliance

- Regulatory Safety – Prevents fines and shutdowns

- CSR Alignment – Builds a responsible and green brand image

PT Ecological Services: Comprehensive ETP Solutions

We offer a complete range of services to support your wastewater treatment goals:

- ETP Design & Engineering

- Turnkey Installation & Commissioning

- Annual Maintenance Contracts (AMC)

- Retrofitting, Expansion & Performance Upgrades

- Sensor Calibration & Compliance Audits

Final Thought

An efficient ETP is more than just a compliance tool—it’s a long-term investment in environmental protection, resource efficiency, and business credibility. At PT Ecological Services, we help industries transition to sustainable operations with smart, reliable, and scalable ETP systems.